Predictive Maintenance in Manufacturing

AI & ML

Predictive Maintenance in Manufacturing

04 Mar, 2025

20 min read

Industrial manufacturers lose an estimated $50 billion each year due to unplanned downtime. Poor maintenance strategies can cut a facility's productive capacity by 20%. These numbers show why predictive maintenance has become significant for modern industrial operations.

Predictive maintenance can revolutionize manufacturing operations. Equipment breakdowns drop by 70% while maintenance costs decrease by 25% compared to traditional methods. The process uses machine-level sensors and data analysis to spot early warning signs of equipment problems, instead of waiting for machines to break down or following strict maintenance schedules.

Predictive maintenance (PdM) in manufacturing leverages data and technology to proactively identify potential equipment failures before they happen. By combining real-time monitoring with advanced analytics, PdM enables businesses to optimize maintenance schedules, reduce downtime, and enhance operational efficiency.

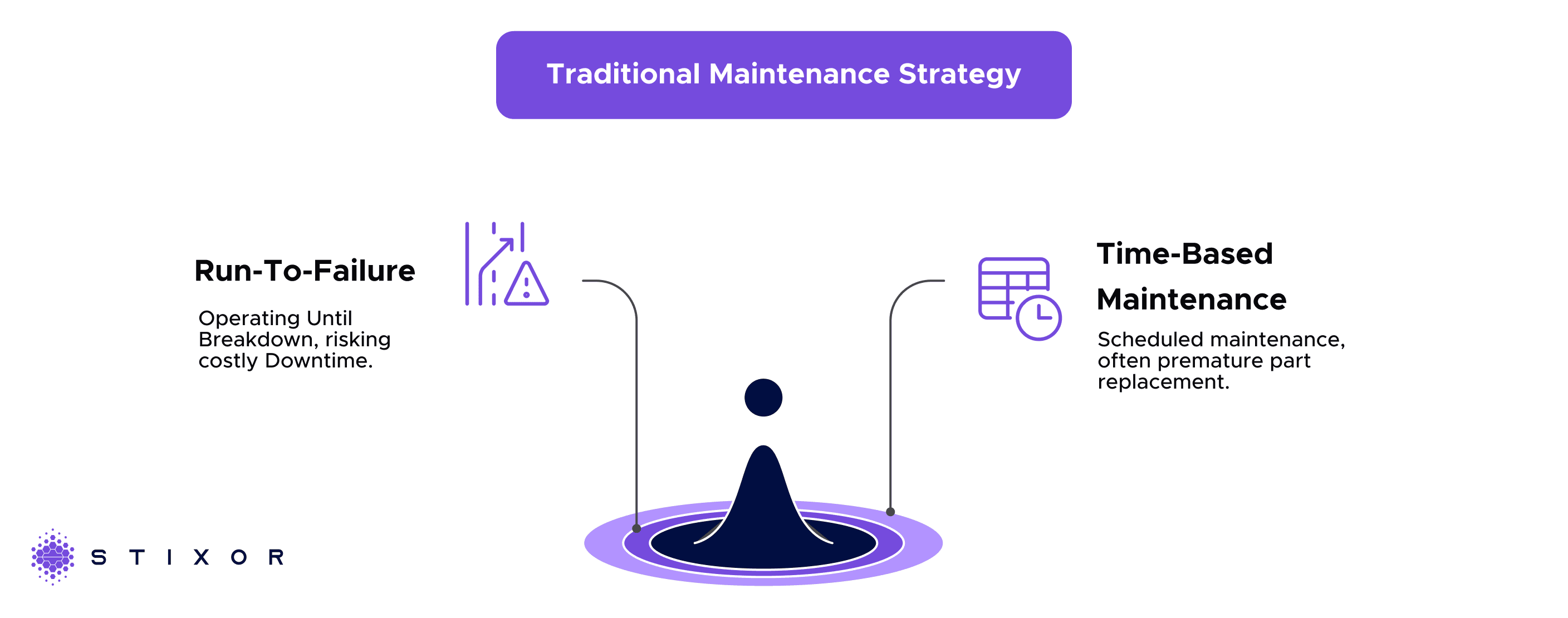

The Challenges of Traditional Maintenance

Historically, manufacturers faced two primary options:

Run-to-Failure: Operating equipment until it breaks down, risking costly unplanned downtime and catastrophic asset damage.

Time-Based Preventive Maintenance: Scheduling maintenance at fixed intervals, often replacing parts prematurely and increasing planned downtime.

“How often should an asset be taken offline to be serviced?” Traditionally, this dilemma forced most maintenance organizations to choose between two options: Maximizing the run time of an asset at the risk of asset downtime (run-to-failure) or maximize reliability of an asset through early replacement of potentially good components (time-based preventive maintenance).

Neither approach guarantees reliability or cost efficiency. Predictive Maintenance provides a forward-thinking alternative, ensuring timely interventions without unnecessary downtime.

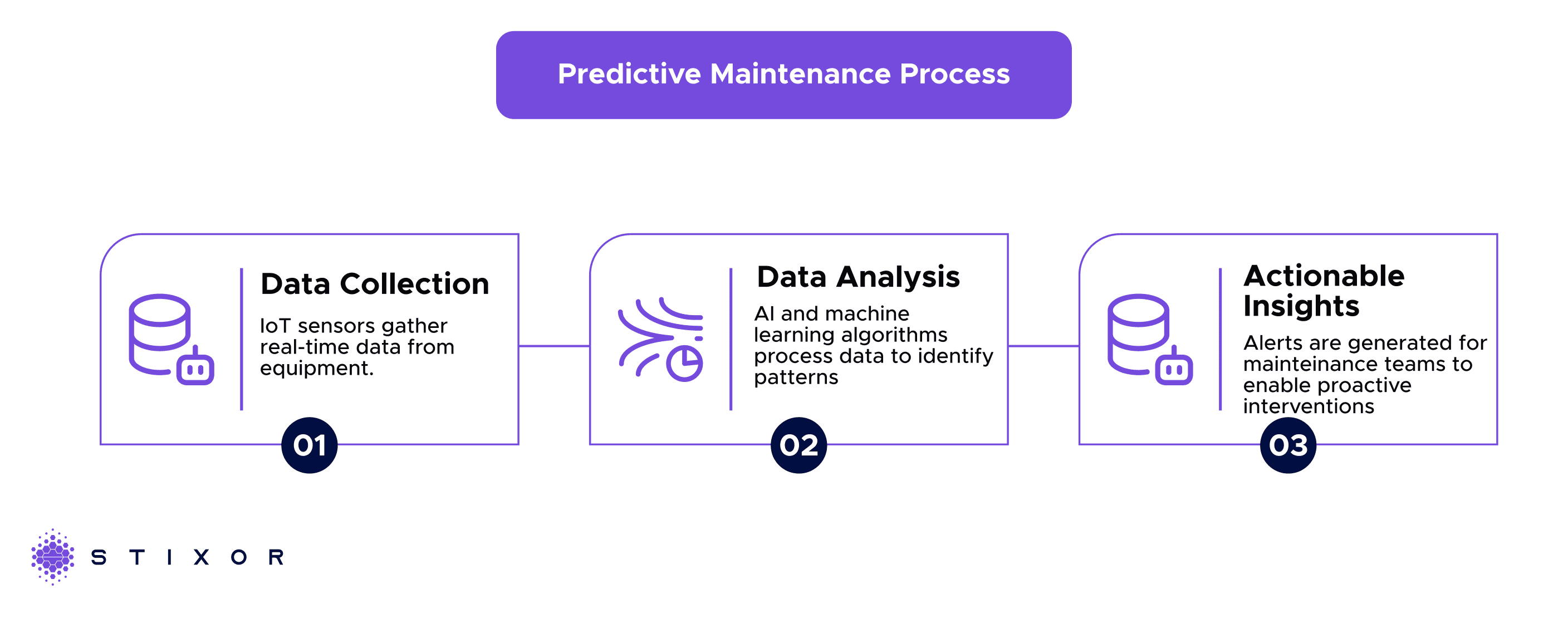

How Predictive Maintenance Works

Predictive Maintenance harnesses the power of Industry 4.0 technologies to monitor equipment health and predict potential failures. Here’s how:

Data Collection: IoT sensors gather real-time data from equipment, such as temperature, vibration, and pressure.

Data Analysis: Advanced AI and machine learning algorithms process this data to identify patterns and predict failures.

Actionable Insights: Alerts are generated for maintenance teams, enabling proactive interventions.

This digital-first approach eliminates guesswork, ensuring efficient maintenance and operational continuity.

Future of Predictive Maintenance in Manufacturing

The Predictive Maintenance market is projected to reach $64.3 billion by 2030, growing at a CAGR of 30%. Innovations in AI, 5G, and edge computing will further enhance its capabilities. Manufacturers adopting these technologies can stay ahead of the curve, ensuring efficiency and profitability in an ever-evolving industry.

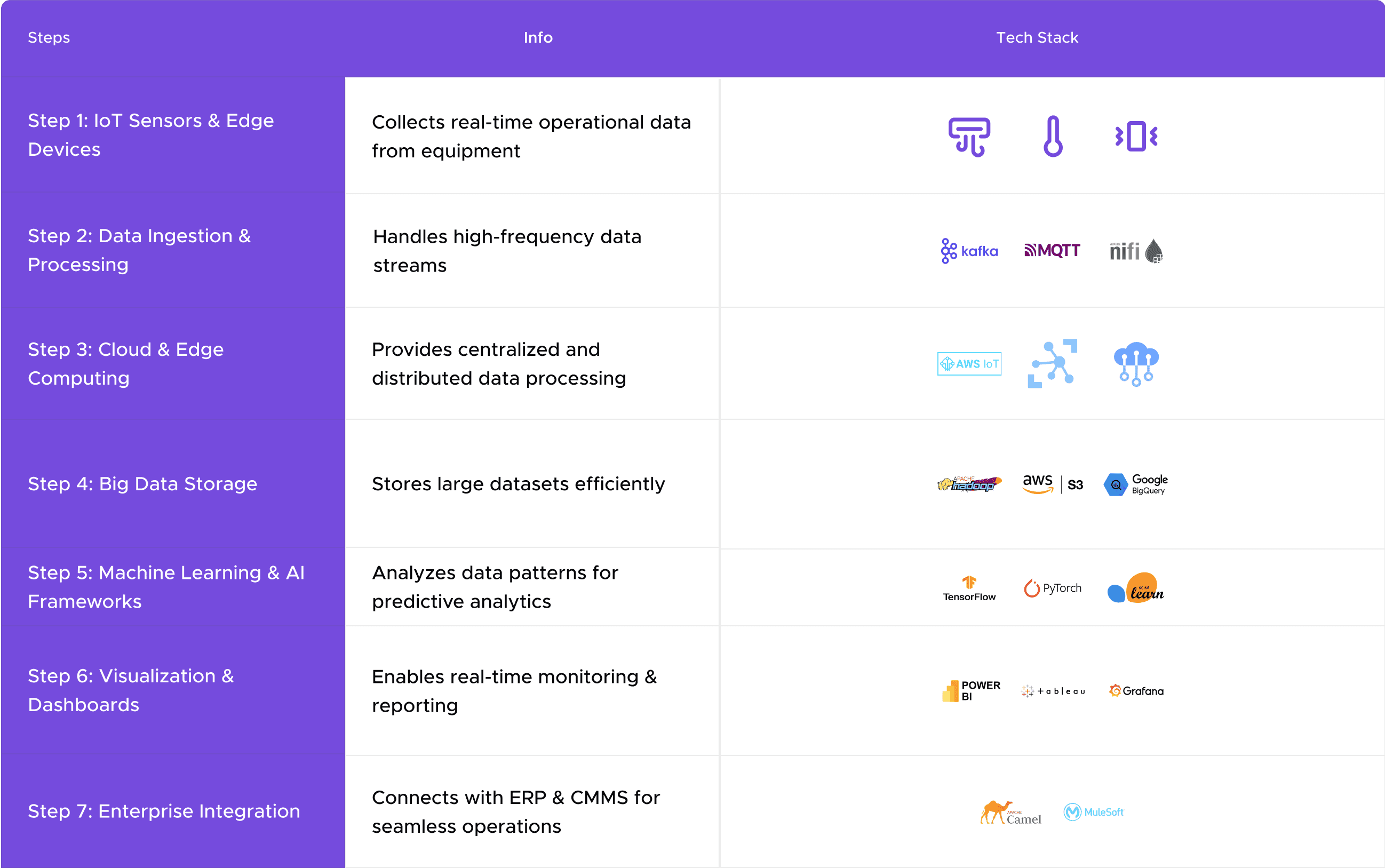

Leveraging Smart Technologies

Predictive Maintenance thrives on an ecosystem of interconnected technologies, including:

IoT Sensors: Real-time data collection on equipment conditions.

AI & Machine Learning: Advanced analytics to detect failure patterns.

Cloud Computing: Centralized storage and processing for large datasets.

PdM shifts the paradigm from "maintenance as a cost center" to "maintenance as a competitive advantage."

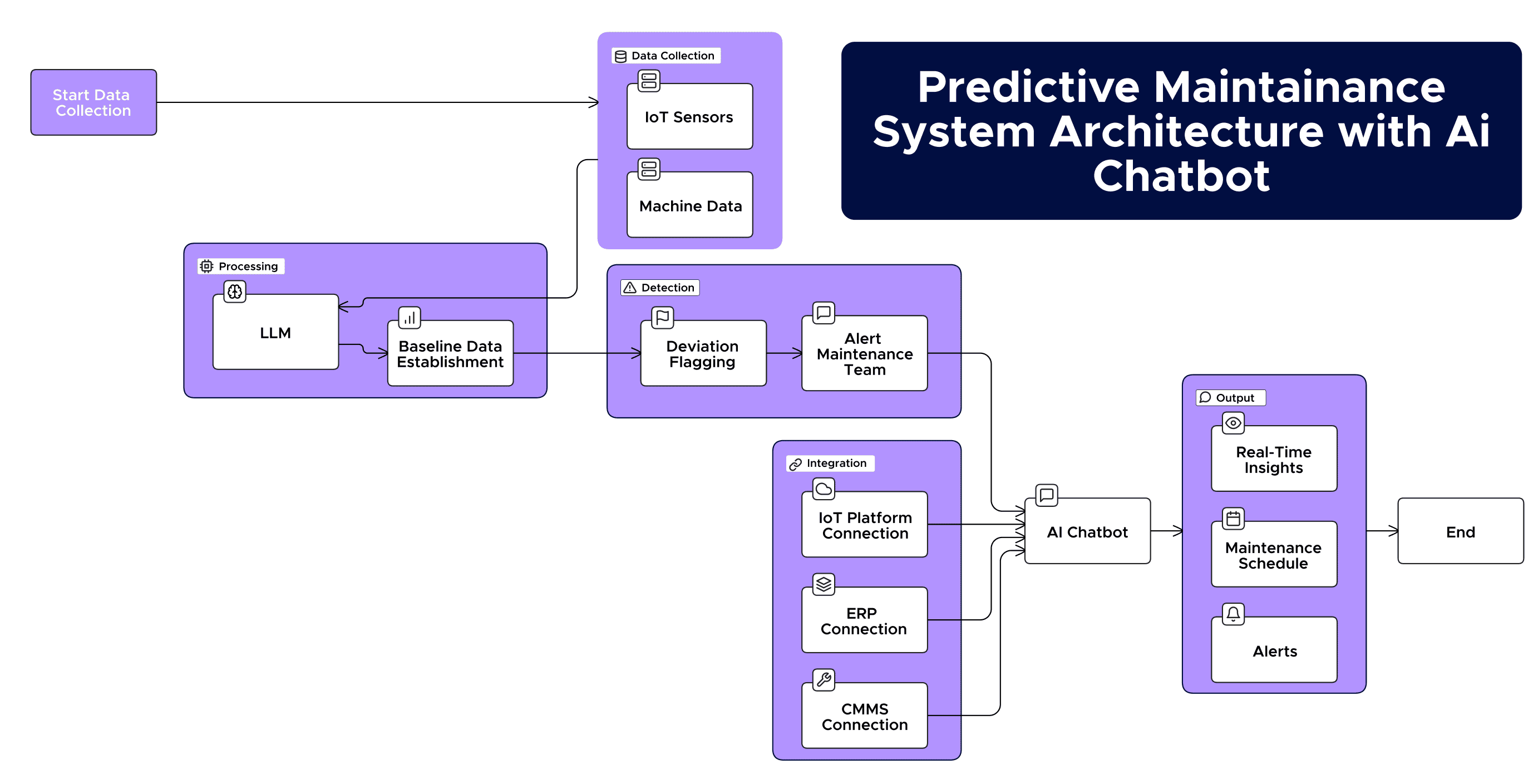

From a systems architecture standpoint, integrating PdM requires:

- A robust IoT framework for seamless data flow

- AI models capable of dynamic learning and adaptation

- A centralized platform for real-time monitoring and alerting

While challenges like data volume management and infrastructure alignment exist, the value proposition is undeniable.

Data Architecture for Smart Manufacturing

A reliable data architecture provides the foundation for effective predictive maintenance systems in manufacturing. Manufacturers can process and analyze equipment data efficiently by implementing edge computing, cloud integration, and data storage solutions strategically.

Edge Computing Layer

Edge devices process data locally near the equipment. This minimizes latency and allows up-to-the-minute decision-making. These computing units use advanced algorithms to analyze sensor readings and identify potential failures without central servers.

The edge layer architecture has:

- Local data filtering and aggregation

- Up-to-the-minute anomaly detection

- Immediate response triggers for critical issues

- Continuous equipment health monitoring

Processing data at the source reduces bandwidth needs. The system keeps running even during network problems. This approach improves data security because sensitive operational information stays within the facility.

Cloud Integration Framework

Cloud computing works alongside edge computing to provide flexible resources for detailed data analysis. Modern cloud frameworks deliver:

Data Integration

- Continuous connection between IoT devices and cloud services

- Automated data synchronization across platforms

- Up-to-the-minute data streaming capabilities

Analytics Processing

- Advanced machine learning model training

- Historical trend analysis

- Predictive algorithm refinement

Cloud platforms provide multi-tenant Software-as-a-Service (SaaS) solutions that improve manufacturing operations through secure, browser-based access to operational data. Manufacturers can grow their operations efficiently without maintaining complex IT infrastructure.

Data Storage Solutions

Time series databases are vital components for storing equipment sensor data. These specialized databases excel at:

- Managing high-volume temporal data

- Providing fast query performance

- Enabling long-term trend analysis

The storage architecture has three main layers:

Raw Data Layer

- Object storage for unstructured data

- Time-stamped sensor readings

- Equipment performance logs

Processing Layer

- Data transformation pipelines

- Aggregation mechanisms

- Quality validation checks

Serving Layer

- Optimized query structures

- Up-to-the-minute analytics support

- Historical data access

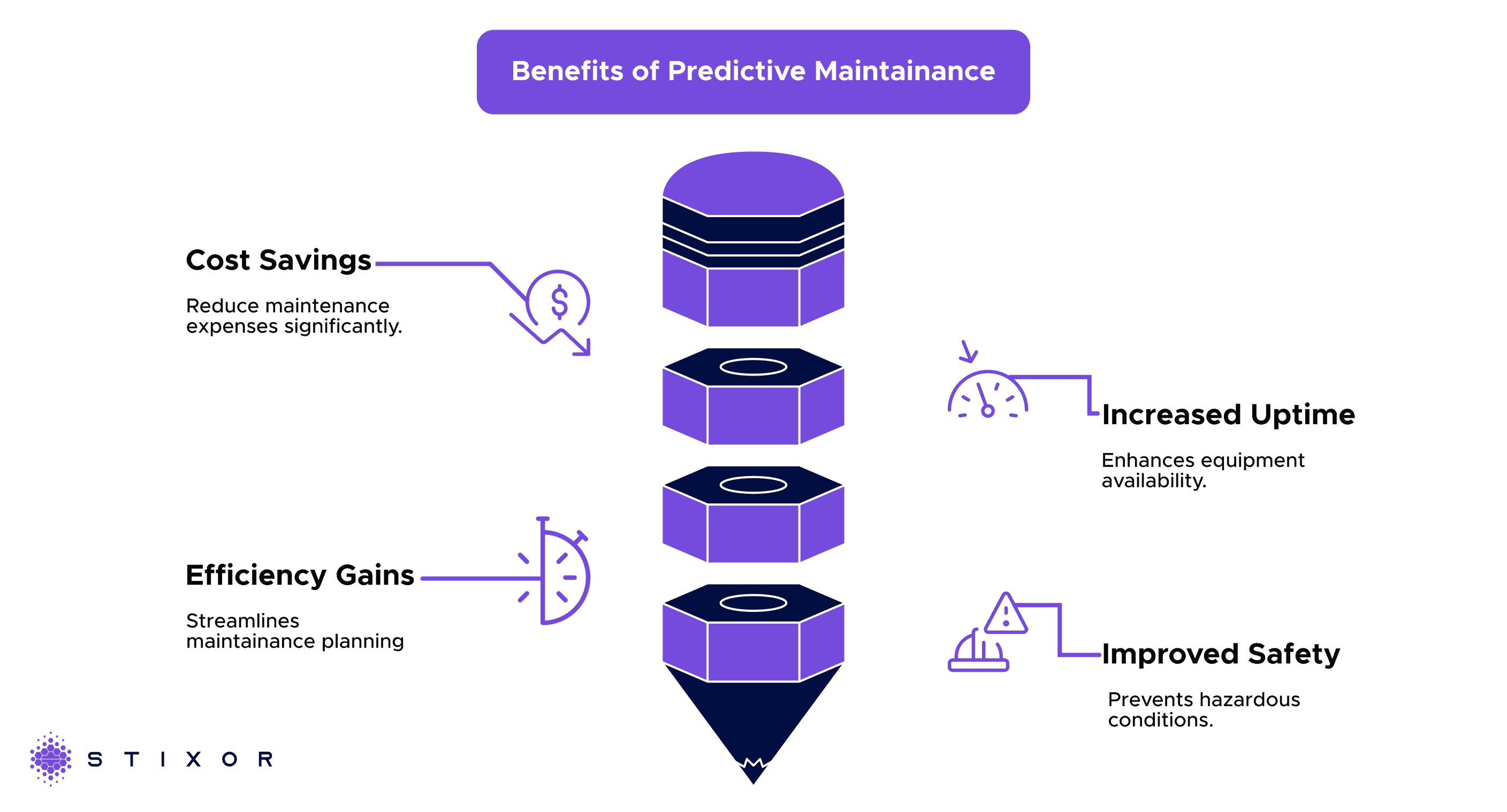

The Benefits of Predictive Maintenance

Companies implementing Predictive Maintenance report a 25% reduction in downtime and a 70% increase in asset reliability.

Stixor’s Predictive Maintenance Solutions

At Stixor, we combine cutting-edge technologies with industry expertise to deliver tailored Predictive Maintenance solutions. Our approach transforms manufacturing processes, ensuring equipment longevity and optimal performance.

Why Choose Stixor?

Industry Expertise: experience in delivering manufacturing solutions.

Tailored Systems: Scalable technologies customized to your unique needs.

End-to-End Integration: Seamless connectivity with existing systems like ERP and CMMS.

Real-Time Dashboards: Intuitive interfaces for actionable insights.

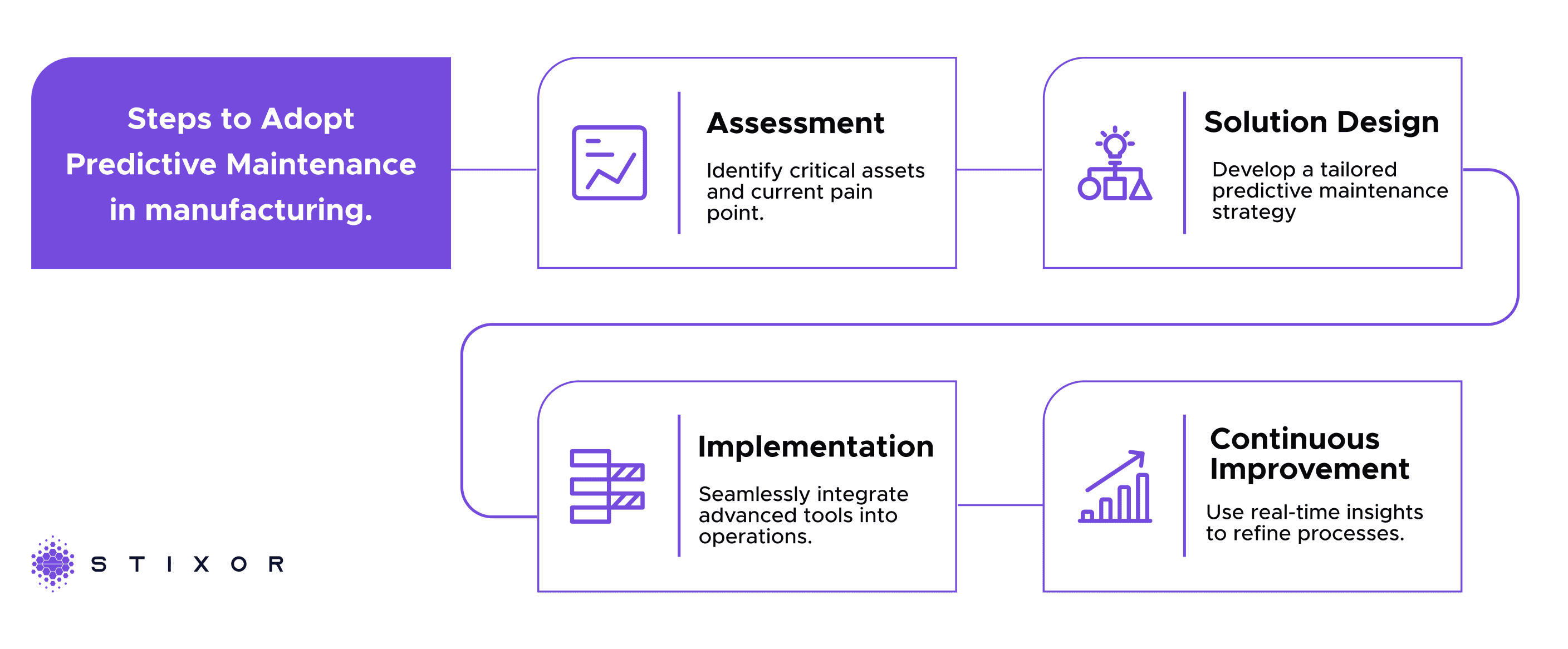

Predictive Maintenance with Stixor

Assessment: We Identify critical assets and current pain points.

Solution Design: We develop a tailored Predictive Maintenance strategy.

Implementation: Seamlessly integrate advanced tools into your operations.

Continuous Improvement: Use real-time insights to refine processes over time.

The Road Ahead: Future-Proof Your Manufacturing with Stixor

Predictive Maintenance is more than a strategy—it’s a revolution in manufacturing efficiency. By adopting Stixor’s advanced solutions, you can ensure your operations are prepared for the demands of the modern industrial landscape.

Ready to take your maintenance strategy to the next level?

Get in touch with Stixor today to explore how Predictive Maintenance can transform your operations.

In this article

- The Challenges of Traditional Maintenance

- How Predictive Maintenance Works

- Leveraging Smart Technologies

- Data Architecture for Smart Manufacturing

- Edge Computing Layer

- Cloud Integration Framework

- Data Storage Solutions

- The Benefits of Predictive Maintenance

- Stixor’s Predictive Maintenance Solutions

- Predictive Maintenance with Stixor

- The Road Ahead: Future-Proof Your Manufacturing with Stixor